Welcome to Weld Axis, a leading innovator in the field of industrial automation. Specializing in the design and manufacture of cutting-edge robot welding positioners, robot gantry systems, and robot linear tracks, we help businesses across the globe enhance productivity, efficiency, and precision. Partnering with top-tier robot integrators such as ABB, KUKA, FANUC, and YASKAWA, we deliver tailored automation solutions that elevate manufacturing processes.

We offer a range of robotic solutions designed to enhance your manufacturing capabilities:

Robot Welding Positioners: Our robot welding positioners are designed to optimize the welding process by positioning workpieces with precision and stability. This allows for consistent high-quality welds, improved productivity, and reduced operator intervention. Our positioners are ideal for applications that require precise orientation and rotation during welding processes.

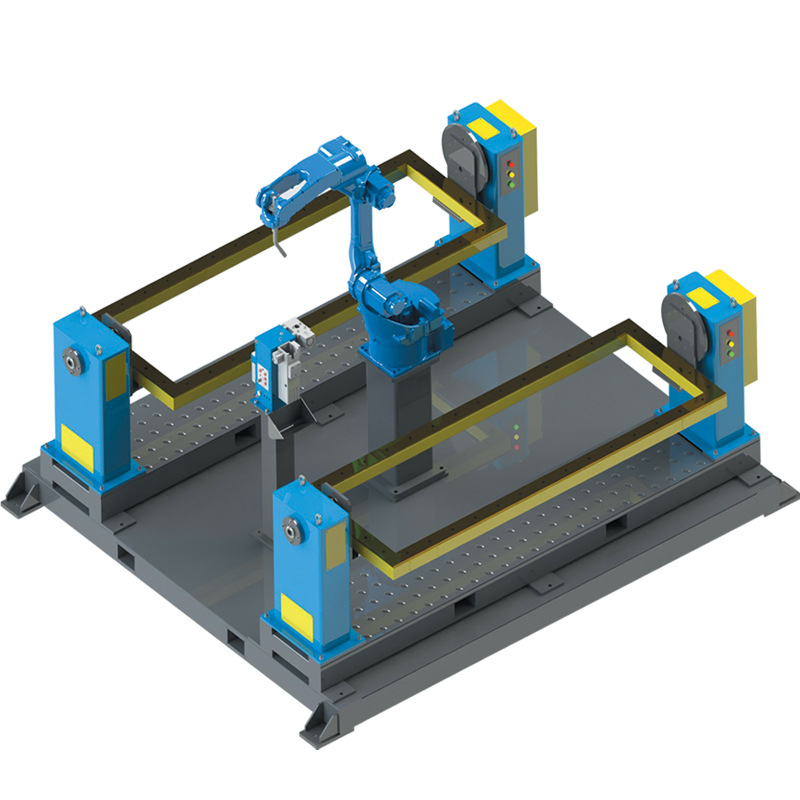

Robot Gantry Systems: The robot gantry systems we offer enable multi-axis movement, allowing robots to perform tasks such as welding, assembly, and material handling across large production areas. These systems are highly flexible, customizable, and perfect for high-volume manufacturing environments. They increase the efficiency of your operations by extending the work envelope of robots and reducing manual labor.

Robot Linear Tracks: Our robot linear tracks are essential for improving the reach and operational efficiency of your robotic systems. These tracks provide linear movement across large production areas, enabling robots to handle tasks in multiple locations without the need for constant repositioning. Perfect for applications where space is a premium, robot linear tracks extend the coverage area and increase workflow efficiency.