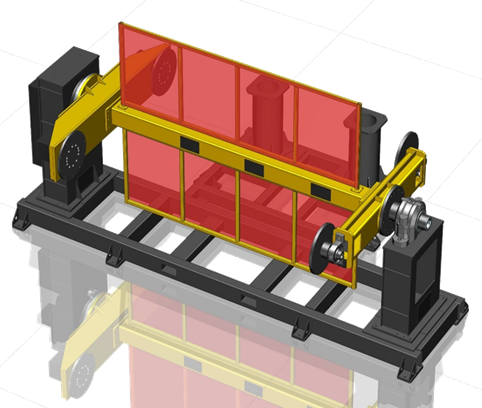

Three Axis Vertical Robot Servo Welding Positioner – Precision, Flexibility, and Heavy-Duty Performance

Product Description:

The Three Axis Vertical Robot Servo Welding Positioner is a cutting-edge solution designed to enhance the accuracy, flexibility, and efficiency of robotic welding operations. Featuring three independent axes of movement—vertical rotation, tilt, and elevation—this positioner allows for precise alignment of workpieces in complex welding applications. The versatile design makes it suitable for a wide range of industries including automotive, aerospace, and heavy equipment manufacturing.

The positioner integrates seamlessly with ABB, KUKA, FANUC, and YASKAWA robots, providing an advanced and automated system that reduces cycle time while improving weld consistency and quality. Its heavy-duty capacity supports large workpieces, enabling operations that require high precision and stability. The vertical orientation ensures that the workpiece is optimally positioned, reducing the need for manual adjustments and increasing productivity.

With servo motor control for smooth, accurate, and repeatable movement, the Three Axis Vertical Welding Positioner is the perfect tool for high-precision robotic welding applications that demand exceptional performance, efficiency, and safety.

Product Features:

Three-Axis Movement: Features vertical rotation, tilt, and elevation, providing precise positioning for various complex welding tasks.

Servo Motor Control: Ensures smooth, accurate, and repeatable movements, optimizing the welding process for high-quality results.

Heavy-Duty Load Capacity: Can support large and heavy workpieces, ideal for demanding industrial applications.

Vertical Orientation Design: The vertical axis ensures optimal positioning and alignment of workpieces, reducing the need for manual adjustments and increasing overall efficiency.

Seamless Robot Integration: Fully compatible with leading robotic systems from ABB, KUKA, FANUC, and YASKAWA for seamless automation integration.

Compact and Space-Saving: Optimized for floor space usage, making it suitable for small to medium-sized workspaces.

User-Friendly Interface: Easy-to-use controls for quick setup and operation, reducing the learning curve for operators.

Durable Construction: Built with industrial-grade materials to ensure longevity and minimal maintenance, even in harsh environments.

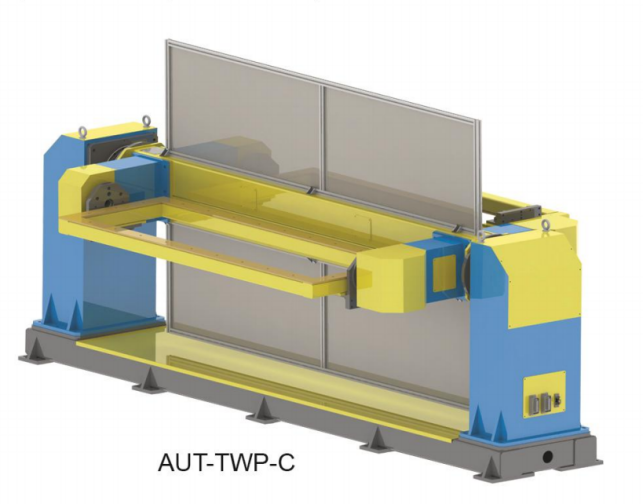

No.

Item

AUT-TWP-C-500

AUT-TWP-C-1000

1

Rated load

500kg (within 2nd axis radius R400mm)

500kg (within 2nd axis radius R500mm)

Standard rotating radius of main axis

R1200mm

R1500MM

2

Standard rotating radius of auxiliary axis

R400mm

R500mm

3

rotary angle of 1st axis

±180°

±180°

4

rotary angle of 2nd axis

±360°

±360°

5

Rated rotary speed of 1st axis

50°/S

24°/S

6

Rated rotary speed of 2nd axis

70°/S

70°/S

7

Repeated positioning accuracy

±0.10mm

±0.15mm

8

Positioner dimension(L×W×H)

4000mm×700mm×1650mm

5200mm×1000mm×1850mm

9

Dimension of the rotary frame (L×W×H)

2200mm x 800mm x 90mm

3200mm x1000mm x 110mm

10

Height of 1st axis rotary center

1350mm

1500mm

11

Power supply

Three phase 200V ±10% 50Hz (with isolation transformer)

Three phase 200V ±10% 50Hz (with isolation transformer)

12

Insulation grade

H

H

13

Weight

about 1800kg

About 3000kg

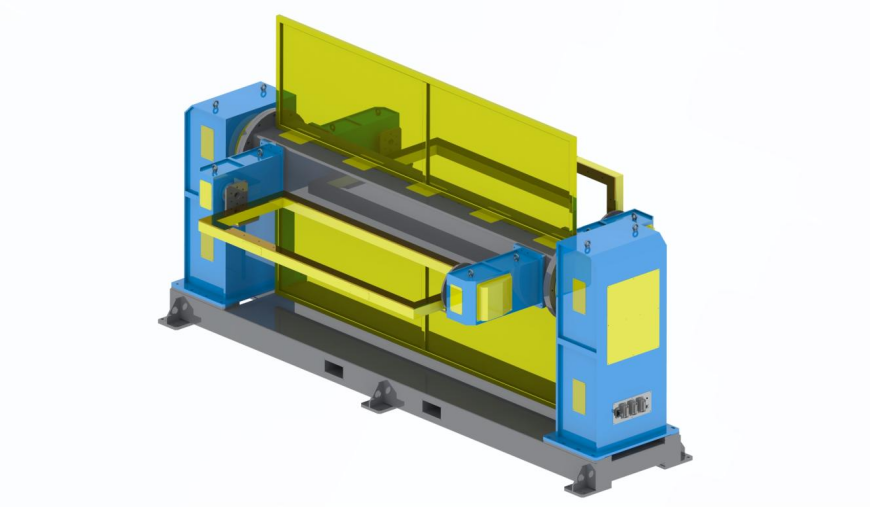

Product Advantages:

Enhanced Precision and Flexibility

The three-axis movement (vertical rotation, tilt, and elevation) provides superior flexibility and precision, enabling accurate workpiece positioning for complex welds, even in tight spaces.Increased Productivity

The automated positioning system reduces the need for manual adjustments, improving cycle times and operational efficiency. This allows for higher throughput in high-volume production environments.Heavy Workpiece Handling

Designed to support large and heavy parts, the Three Axis Vertical Positioner is ideal for industries that require welding of large components, such as aerospace, automotive, and heavy machinery manufacturing.Compact and Space-Efficient

The vertical orientation design ensures that the positioner occupies less floor space while maintaining a high load capacity, making it perfect for facilities with limited space.Seamless Robotic Integration

Compatible with top robotic arms and controllers from ABB, KUKA, FANUC, and YASKAWA, this positioner integrates effortlessly into automated welding systems, enhancing overall productivity.Durability and Low Maintenance

Constructed with high-quality materials, the positioner is designed to handle demanding industrial environments, offering long-lasting durability and low maintenance requirements.Improved Operator Safety

By automating workpiece positioning, the Three Axis Vertical Positioner reduces manual handling and operator interaction with the welding process, improving overall safety in the workplace.Versatile for Multiple Applications

Whether welding small parts or large components, this positioner adapts to a variety of welding applications, making it a versatile tool for different industries and tasks.