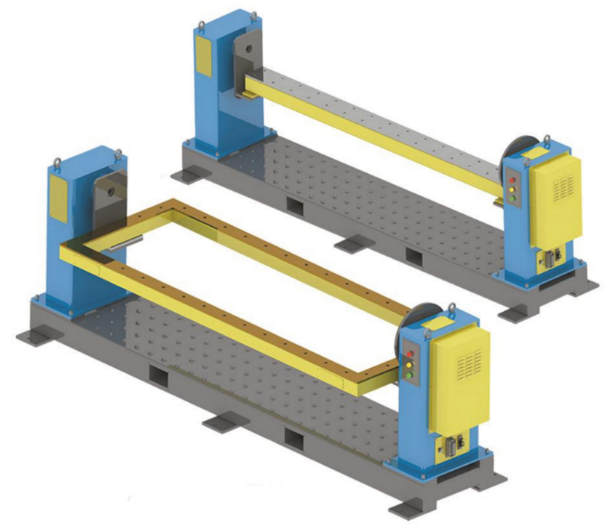

Single axis head and tail frame rotation robot welding positioner for Industrial Automation

Robot Welding Positioners: Our robot welding positioners are designed to optimize the welding process by positioning workpieces with precision and stability. This allows for consistent high-quality welds, improved productivity, and reduced operator intervention. Our positioners are ideal for applications that require precise orientation and rotation during welding processes.

Technical Specification:

NO | Item | SWP-ZW-300 | SWP-ZW-500 | SWP-ZW-1000 | SWP-ZW-2000 |

1 | Rated load | 300kg(Within 350mm radius of axis) | 500kg(Within 400mm radius of axis) | 1000kg(Within 600mm radius of axis) | 2000kg(Within 1000mm radius of axis) |

2 | Full load eccentricity distance | ≤200mm (Total clamping height ≤ 550mm) | ≤150mm(Total clamping height ≤400mm) | ≤200mm(Single-sided clamping Total height ≤ 550mm) | ≤200mm(Single-sided clamping Total height ≤ 450mm) |

3 | Rated radius of rotation | R600mm | R650mm | R750mm | R1100mm |

4 | Rated rotation angle | ±360° | ±360° | ±360° | ±360° |

5 | Rated rotation speed | 70°/S | 50°/S | 50°/S | 50°/S |

6 | Repeated positioning accuracy | ±0.06mm ( R=350mm) | ±0.08mm (R=400mm) | ±0.10mm( R=700mm) | ±0.18mm(R=1000mm) |

7 | Rotary frame size (LxWxH) | 2000mm×660mm×90mm | 2200mm×800mm×90mm | 3000mm×1200mm×130mm | 3000mm×2000mm |

8 | Positioner dimension (L×W×H) | 2820mm×700mm×960mm | 2900mm×700mm×1050mm | 3900mm×800mm×1200mm | 4000mm×950mm×1500mm |

9 | Standard rotary plate | Φ360mm | Φ360mm | Φ390mm | Φ450mm |

10 | Height of rotary center | 760mm | 830mm | 950mm | 1300mm |

11 | Equipment net weight | 400kg | 500kg | 800kg | 1300kg |

Why Choose Our Welding Positioners?

Enhanced Welding Quality

Our robot welding positioners provide optimal positioning, ensuring the workpiece remains stable and at the correct angle during welding. This results in high-quality, uniform welds across multiple cycles, reducing defects and rework.

Increased Productivity

By automating the positioning of parts, our positioners significantly reduce the time spent on manual handling and adjustments. This boosts overall productivity by allowing your robotic systems to operate continuously without interruptions.

Improved Safety

Welding can be a hazardous task, especially when manual handling is involved. Our positioners reduce operator interaction with hazardous equipment, improving workplace safety and reducing the risk of injury.

Customizable for Various Applications

Whether you are welding small parts or large, heavy components, our welding positioners are highly adaptable to different shapes, sizes, and materials. We offer customizable solutions that fit your specific welding needs, making our positioners ideal for a wide range of industries.

Durable & Long-Lasting

Built with high-quality materials, our welding positioners are designed for durability and long-term use in industrial environments. They are engineered to withstand the demands of high-volume, heavy-duty production, ensuring reliability and minimal maintenance.

Robot Welding Positioners: Our robot welding positioners are designed to optimize the welding process by positioning workpieces with precision and stability. This allows for consistent high-quality welds, improved productivity, and reduced operator intervention. Our positioners are ideal for applications that require precise orientation and rotation during welding processes.

Technical Specification:

NO | Item | SWP-ZW-300 | SWP-ZW-500 | SWP-ZW-1000 | SWP-ZW-2000 | SWP-ZW-3000 | SWP-ZW-5000-WT-CT | SWP-ZW-5000

|

1 | Rated load | 300kg(Within 350mm radius of axis) | 500kg(Within 400mm radius of axis) | 1000kg(Within 600mm radius of axis) | 2000kg(Within 1000mm radius of axis) | 3000kg(Within 1000mm radius of axis) | 5000kg(Within 12500mm radius of axis) | 5000kg(Within 1250mm radius of axis) |

2 | Full load eccentricity distance | ≤200mm (Total clamping height ≤ 550mm) | ≤150mm(Total clamping height ≤400mm) | ≤200mm(Single-sided clamping Total height ≤ 550mm) | ≤200mm(Single-sided clamping Total height ≤ 450mm) | ≤200mm(Single-sided clamping Total height ≤ 400mm) | ≤300mm(Single-sided clamping Total height ≤700mm) | ≤300mm(Single-sided clamping Total height ≤700mm) |

3 | Rated radius of rotation | R600mm | R650mm | R750mm | R1100mm | R1250mm | R1500mm | R1500mm |

4 | Rated rotation angle | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° |

5 | Rated rotation speed | 70°/S | 50°/S | 50°/S | 50°/S | 50°/S | 28°/S | 28°/S |

6 | Repeated positioning accuracy | ±0.06mm ( R=350mm) | ±0.08mm (R=400mm) | ±0.10mm( R=700mm) | ±0.18mm(R=1000mm) | ±0.20mm(R=1000mm) | ±0.25mm(R=1250mm) | ±0.25mm(R=1250mm) |

7 | Rotary frame size (LxWxH) | 2000mm×660mm×90mm | 2200mm×800mm×90mm | 3000mm×1200mm×130mm | 3000mm×2000mm | 4500mm×2000mm | (0-10000)mm×2500mm | (0-10000)mm×2500mm |

8 | Positioner dimension (L×W×H) | 2820mm×700mm×960mm | 2900mm×700mm×1050mm | 3900mm×800mm×1200mm | 4000mm×950mm×1500mm | 5600mm×1000mm×1700mm | (5000-11000)mm×1350mm×2100mm | (5000-11000)mm×1350mm×2100mm |

9 | Standard rotary plate | Φ360mm | Φ360mm | Φ390mm | Φ450mm | Φ450mm | Φ800mm | Φ800mm |

10 | Height of rotary center | 760mm | 830mm | 950mm | 1300mm | 1450mm | 1750mm | 1750mm |

11 | Equipment net weight | 400kg | 500kg | 800kg | 1300kg | 1800kg | 3T-10T | 3T-10T |

12 | Lifting stroke | / | / | / | / | / | 1000mm | / |

13 | Adjustable tailgate travel | / | / | / | / | / | 0-5000mm | / |

14 | Rated lifting speed | / | / | / | / | / | 0-800mm/min | / |

15 | Tailgate travel speed | / | / | / | / | / | 0-10000mm/min | / |

Why Choose Our Welding Positioners?

Enhanced Welding Quality

Our robot welding positioners provide optimal positioning, ensuring the workpiece remains stable and at the correct angle during welding. This results in high-quality, uniform welds across multiple cycles, reducing defects and rework.Increased Productivity

By automating the positioning of parts, our positioners significantly reduce the time spent on manual handling and adjustments. This boosts overall productivity by allowing your robotic systems to operate continuously without interruptions.Improved Safety

Welding can be a hazardous task, especially when manual handling is involved. Our positioners reduce operator interaction with hazardous equipment, improving workplace safety and reducing the risk of injury.Customizable for Various Applications

Whether you are welding small parts or large, heavy components, our welding positioners are highly adaptable to different shapes, sizes, and materials. We offer customizable solutions that fit your specific welding needs, making our positioners ideal for a wide range of industries.Durable & Long-Lasting

Built with high-quality materials, our welding positioners are designed for durability and long-term use in industrial environments. They are engineered to withstand the demands of high-volume, heavy-duty production, ensuring reliability and minimal maintenance.