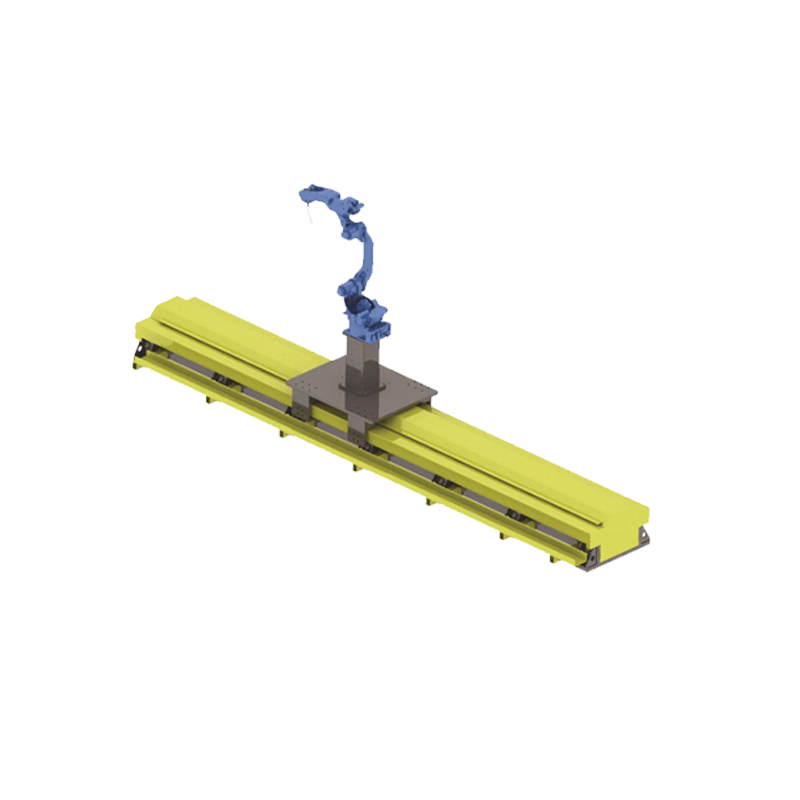

Robot Linear Track – High Precision and Durability for Robotic Automation Systems

Product Description:

The Robot Linear Track is an advanced, precision-engineered solution designed to extend the reach and enhance the flexibility of robotic arms in automated systems. Ideal for applications requiring linear motion, the Robot Linear Track allows robots to move along a predefined path with high accuracy, increasing productivity and enabling seamless integration with other automated machinery. Whether for material handling, welding, assembly, or inspection, the linear track improves operational efficiency by providing consistent, smooth motion in robotic systems.

Crafted from durable, high-quality materials, this linear track offers superior stability, precision, and long-term performance, ensuring minimal downtime and extended equipment lifespan. Designed for easy integration with various robotic arms, including ABB, KUKA, FANUC, and YASKAWA, the Robot Linear Track delivers reliability and flexibility in every application. It is perfect for manufacturing, heavy industries, and other applications where robots need to cover larger workspaces or require precise linear movements.

No. | Item | Light payload robot track | Medium payload robot track | Heavy payload robot track |

1. | Product name | Single-axis servo ground rail (light load) | Single axis servo ground rail (medium sized) | Single axis servo ground rail (Heavy duty) |

2. | Main use | Welding, light loading | Welding, handling and loading | Welding, handling, multi-axis walking base |

3. | Model | SW-X-Z-L-Length | SW-X-Z-M-Length | SW-X-Z-CZ-Length |

4. | Number of control axis | Single axis (X direction) | Single axis (X direction) | Single axis (X direction) |

5. | Control method | Control based on precision AC servo motor | Electrical Control Based on Precision AC Servo Motor | Electrical Control Based on Precision AC Servo Motor |

6. | Installation form | Ground-mounted formal installation | Ground-mounted formal wear | Ground-mounted formal wear |

7. | Drive mode | Gear and rack drive | Gear and rack drive | Gear and rack drive |

8. | Gear and rack form | Precision helical teeth | Precision helical teeth | Precision helical teeth |

9. | Guide type | Linear guide and slide | Linear guide and slide | Linear guide and slide |

10. | Reducer | Precision planetary reducer | Precision Planetary Reducer | Precision Planetary Reducer |

11. | Reducer speed ratio | i=20 | i=20 | i=40 |

12. | Repeating accuracy | ±0.08mm | ±0.10m | ±0.15m |

13. | Moving speed | 0-40000mm/min | 0-40000mm/min | 0-20000mm/min |

14. | Effective stroke length | length-800mm | Length-1400mm | Length-1500mm |

15. | The effective installation size of the slide table | 450mm×500mm(length×width) | 900mm×750mm(L×W) | 1000mm×1100mm(L×W) |

16. | Maximum load | Total load≤800kg The end load of the handling robot≤50kg | Total load≤3000kg The end load of the handling robot≤300kg | Total load≤10000kg The end load of the handling robot≤1000kg |

17. | Dimensions | Length x 900mm x 800mm (height of the shield) | Length x 1270mm x 900mm (shield height) | Length×1700mm×1100mm (shield height) |

18. | Cable drag chain position | center/external (towline inner cavity 45×75+45×75) | Central/external (drag chain inner cavity 45×75+45×75) | Central/external (drag chain inner cavity 45×125+45×125) |

19. | Weight | Length×150kg/m+150kg (weight of slide assembly) | Length×300kg/m+420kg (weight of slide assembly) | Length×450kg/m+800kg (weight of slide assembly) |

Product Features:

High Precision Linear Motion: Provides accurate, repeatable motion for robotic systems, ideal for welding, material handling, and assembly tasks.

Durable Construction: Built with high-strength materials for long-lasting durability and minimal maintenance in industrial environments.

Increased Reach: Extends the range of robotic arms, allowing them to cover larger areas without the need for additional robotic units.

Seamless Integration: Compatible with leading robotic systems such as ABB, KUKA, FANUC, and YASKAWA, ensuring smooth integration with existing automation setups.

Smooth Operation: Features a high-quality track system that ensures smooth, continuous motion, reducing the risk of jamming and enhancing the efficiency of your automation.

Customizable Length and Speed: Adjustable length and speed options to suit a variety of robotic applications and production requirements.

Space-Efficient Design: The compact design ensures optimal use of floor space, making it ideal for operations with space constraints.

Product Advantages:

Enhanced Flexibility

The Robot Linear Track expands the robotic system’s reach and flexibility, allowing robots to perform tasks across a larger workspace, improving overall operational capabilities.Improved Efficiency and Productivity

By enabling robots to move along a linear path, the track reduces cycle times and enhances production throughput, leading to more efficient operations and faster task completion.Durable and Low-Maintenance

Designed for heavy-duty industrial use, the track’s robust construction ensures long-term reliability and minimizes the need for frequent maintenance, reducing downtime and operating costs.Smooth and Precise Motion

The precision-engineered track offers smooth, consistent motion with minimal friction, which improves the quality of robotic tasks and reduces the risk of mechanical failure or wear.Seamless Robotic Integration

Compatible with top robotic arms from industry leaders like ABB, KUKA, FANUC, and YASKAWA, ensuring an easy, hassle-free integration into your automated systems.Scalable and Customizable

The Robot Linear Track can be customized to meet specific application requirements, including length, speed, and weight capacity, providing a tailored solution for your business needs.

Applications:

Welding Automation: Increases the flexibility and reach of robotic welding arms for precise and consistent welds across larger workpieces.

Material Handling: Enables robotic arms to transport heavy or large materials over extended distances with smooth, efficient motion.

Assembly Line Automation: Provides linear motion for robots involved in assembly tasks, improving productivity and part placement accuracy.

Inspection and Testing: Supports automated inspection and testing operations by allowing robots to move along a fixed path with high precision.

Packaging: Ideal for packaging applications, enabling robots to transport and position products along assembly lines or packaging stations.