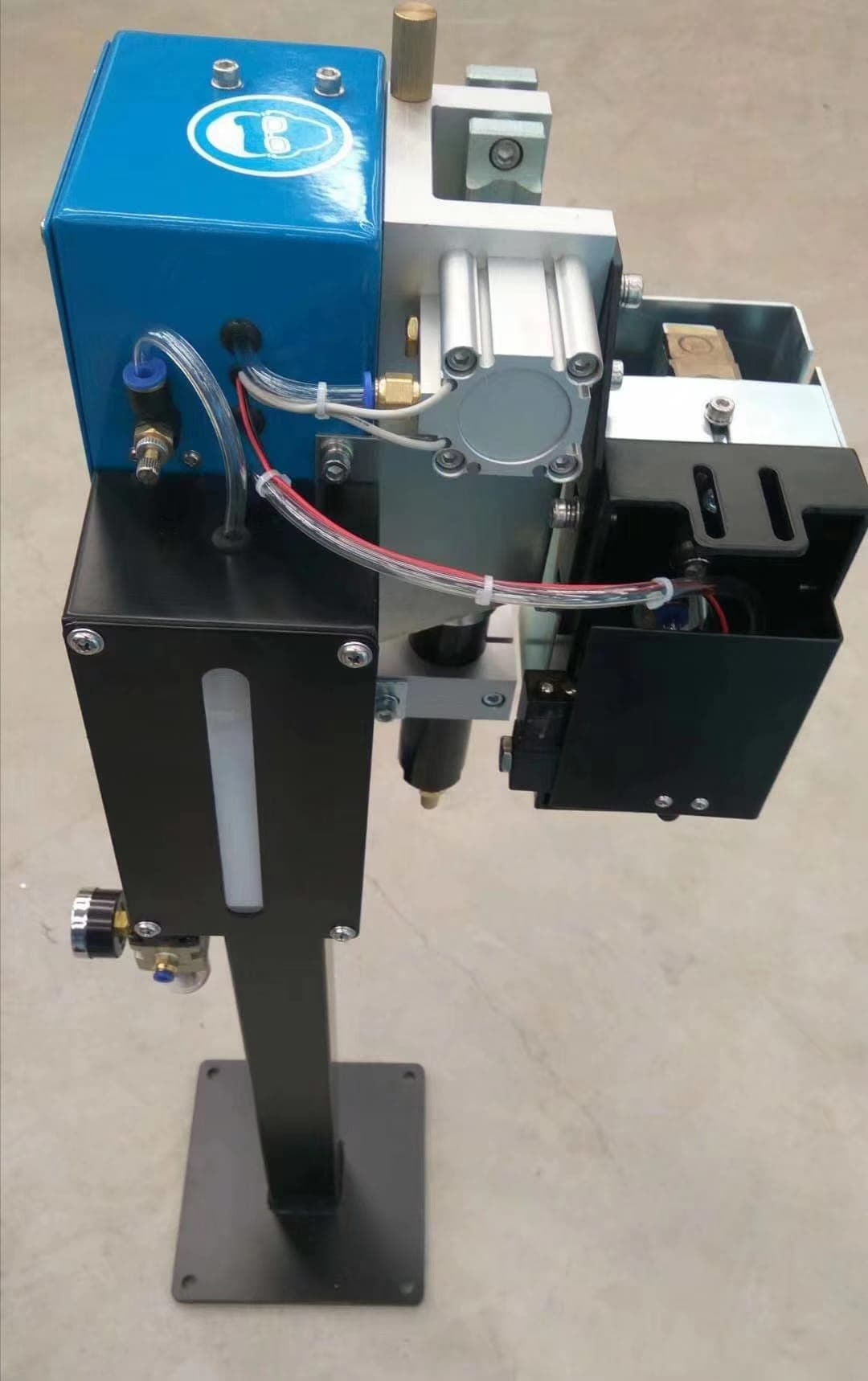

Torch Cleaning Station – High-Efficiency Cleaning System for Robotic Welding Torches

Product Description:

The Torch Cleaning Station is an advanced cleaning solution designed to keep your robotic welding torches in optimal working condition. This essential equipment is engineered to automatically clean the welding torch tips, removing dirt, spatter, and contaminants that can impair the quality of welds. Ideal for industries such as automotive, aerospace, and manufacturing, the Torch Cleaning Station helps to maintain consistent weld quality, reduce downtime, and extend the lifespan of your welding equipment.

Equipped with automatic cleaning cycles, the station ensures that your welding torches are always ready for precise, high-quality welding. Its compact, easy-to-use design saves valuable time and improves the overall efficiency of your welding operation. The Torch Cleaning Station is compatible with various torch types and integrates seamlessly into your existing robotic welding systems, enhancing automation while reducing manual maintenance.

By using the Torch Cleaning Station, you not only improve the cleanliness of your welding tools but also increase productivity, reduce the risk of defects, and improve the quality of each weld. Experience reliable performance and reduced maintenance costs with this efficient cleaning solution.

No | Item | Parameter |

1 | Model | JY-2000s

|

2 | Compressed air source | Oil-free dry air |

3 | Required gas volume | Approximately 10L per second |

4 | program control | pneumatically operated |

5 | input voltage | U=24V

|

6 | Clearance time | About 4-5 seconds |

7 | Anti-splash agent volume | 500ml

|

8 | Anti-splash spray volume | adjustable |

9 | Weight | 23kg |

Torch Cleaning Device Features

A Torch Cleaning Device is an essential tool for maintaining the performance and longevity of robotic welding torches. Designed to automate the cleaning process, it ensures consistent weld quality, reduces downtime, and extends the life of your welding equipment. Here are its key features:

1. Automated Cleaning Process

Efficiency: Automatically cleans the torch nozzle, contact tip, and diffuser without manual intervention.

Consistency: Ensures uniform cleaning for every weld cycle, reducing variability in weld quality.

2. High-Precision Cleaning

Nozzle Reaming: Removes spatter and debris from the nozzle with precision, preventing blockages.

Tip Cleaning: Cleans the contact tip to maintain optimal electrical conductivity and arc stability.

3. Durability and Reliability

Robust Construction: Built with high-quality materials to withstand harsh industrial environments.

Long Service Life: Designed for continuous operation with minimal maintenance requirements.

4. Compatibility

Multi-Brand Support: Compatible with torches from leading brands like ABB, FANUC, KUKA, and YASKAWA.

Versatile Integration: Easily integrates into existing robotic welding systems.

5. Time and Cost Savings

Reduced Downtime: Minimizes interruptions for manual cleaning, keeping production lines running smoothly.

Lower Consumable Costs: Extends the life of nozzles, contact tips, and diffusers, reducing replacement frequency.

6. User-Friendly Design

Easy Installation: Simple to set up and integrate into your welding cell.

Low Maintenance: Self-cleaning mechanisms reduce the need for frequent servicing.

7. Safety Features

Protective Housing: Shields operators from heat and spatter during the cleaning process.

Automated Safety Checks: Ensures safe operation by detecting and addressing issues during cleaning.

8. Customizable Options

Adjustable Cleaning Cycles: Tailor cleaning frequency and intensity to match your welding process.

Compact Design: Available in various sizes to fit different workspace requirements.

Applications

Robotic Welding Cells: Ideal for automated welding systems in automotive, aerospace, and heavy machinery industries.

High-Volume Production: Perfect for environments with continuous welding operations.

Precision Welding: Ensures clean, high-quality welds for critical applications.

Why Choose a Torch Cleaning Device?

Improved Weld Quality: Consistent cleaning ensures reliable arc performance and weld integrity.

Increased Productivity: Reduces manual cleaning time, allowing operators to focus on core tasks.

Cost-Effective: Lowers operational costs by extending consumable life and reducing downtime.