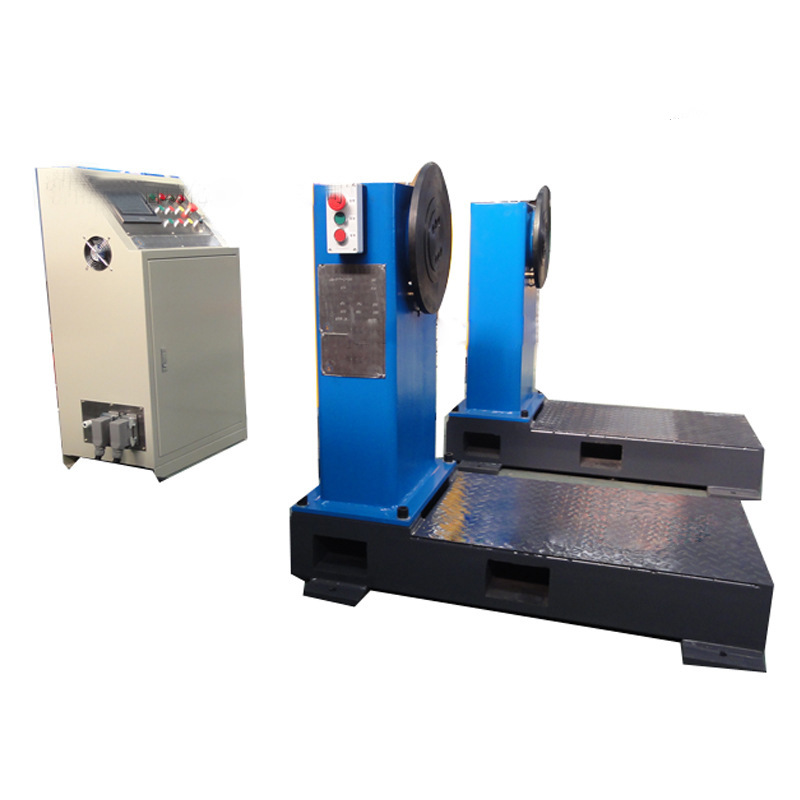

Single Axis Spindle Robot Servo Welding Positioner – Precision Welding Automation Solution

Features

High-Precision Servo Motor: Ensures accurate positioning and smooth operation.

Single Axis Design: Simplifies integration and reduces setup time.

Heavy-Duty Construction: Built to withstand demanding industrial environments.

360° Continuous Rotation: Enables flexible welding angles for complex tasks.

Compatible with Major Robot Brands: Works seamlessly with ABB, KUKA, FANUC, and YASKAWA robots.

User-Friendly Interface: Easy to program and operate, reducing training time.

Low Maintenance: Durable components ensure long service life with minimal upkeep.

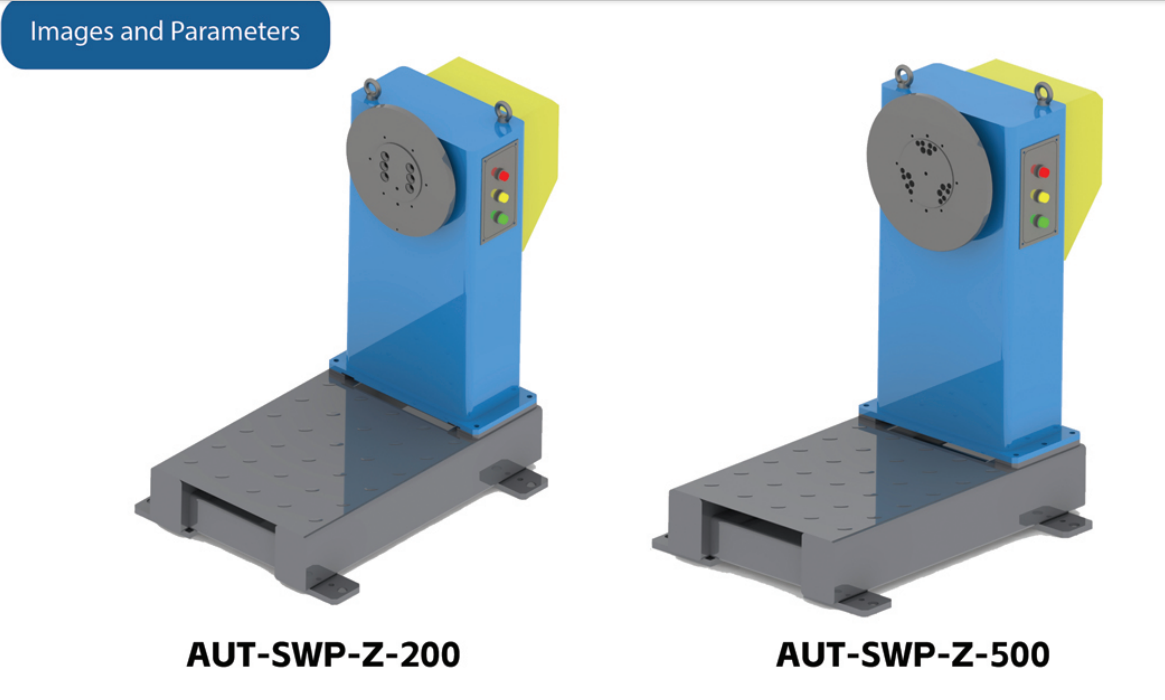

No.

Item

SWP-Z-200

SWP-Z-500

1

Rated load

200kg (within main axis radius R300mm, center of gravity ≤ 300mm from flange)

500kg (within main axis radius R400mm, center of gravity ≤ 300mm from flange)

2

Standard radius of rotary

R600mm

R600mm

3

Maximum angle of rotary

±360°

±360°

4

Rated speed of rotary

70°/S

70°/S

5

Repeated positioning accuracy

±0.08mm

±0.10mm

6

Main axis rotary disk size

φ360mm

φ800

7

Positioner dimension(L×W×H)

1050mm×620mm×1050mm

1200mm×750mm×1200mm

8

Height of rotary center

850mm

900mm

9

Power supply

Three phase 200V ±10% 50Hz (with isolation transformer)

Three phase 200V ±10% 50Hz (with isolation transformer)

10

Insulation grade

H

H

11

Self weight

about 200kg

about 300kg

Product Description

The Single Axis Spindle Robot Servo Welding Positioner is a state-of-the-art solution designed to enhance precision and efficiency in robotic welding applications. Featuring a high-performance servo motor and robust construction, this positioner delivers 360° continuous rotation and precise positioning for optimal weld quality. Compatible with leading robot brands like ABB, KUKA, FANUC, and YASKAWA, it is ideal for industries such as automotive, aerospace, and heavy machinery. Its user-friendly design and low maintenance requirements make it a cost-effective choice for automated welding systems.

Advantages

Improved Weld Quality: Ensures consistent and precise welds, reducing rework.

Increased Productivity: Automates workpiece positioning, reducing cycle times.

Versatile Applications: Suitable for welding, assembly, and material handling tasks.

Cost-Effective: Reduces labor costs and minimizes downtime.

Scalable Solution: Easily integrates into existing production lines for future expansion.